Waht’s the surface technology of bulletproof plates?

There are many types of surface technology of bulletproof plates, generally divided into two categories: polyurea coating and cloth cover.

The cloth cover is a layer of waterproof fabric wrapped around the surface layer of the bulletproof plates. It has the characteristics of simple processing and low price.

The polyurea coating (X-Line) is to spray polyurea evenly on the surface of the bulletproof plates. The polyurea coating will bring extra weight. But it can also achieve a certain defense effect, and the bullet holes after the bullets are injected are also smaller than the bullet holes of the bulletproof plates, covering the assumed surface. However, the price of the bulletproof plates using the polyurea coating will be more expensive than the board using the cloth cover.

Understanding of ballistic material

Steel= Heavy, thin, unsafe shattering of bullet, and cheapest to make.

= Short lifespan, lighter than steel, very low durability.

PE= The lightest, a bit more expensive, longer lasting, most effective, safest. Weight for weight, 40% stronger than kevlar and more than 10 times stronger than steel.

What is the principle of bulletproof vest

(1) Deformation of the fabric: including the deformation of the bullet incident direction and the tensile deformation of the area near the incident point;

(2) Destruction of fabrics: including fibrillation of fibers, breakage of fibers, disintegration of yarn structure and disintegration of fabric structure;

(3) Thermal energy: Energy is dissipated in the form of thermal energy through friction;

(4) Acoustic energy: the energy consumed by the sound emitted by the bullet after hitting the bulletproof layer;

(5) Deformation of the projectile: the soft and hard composite body armor developed for improving the bulletproof capability, the bulletproof mechanism of which can be summarized by "soft and hard". When the bullet hits the bulletproof vest, the first thing to interact with it is hard bulletproof materials such as steel plates or reinforced ceramic materials. During this moment of contact, both the bullet and the hard bulletproof material may deform or break, consuming most of the bullet's energy. The high-strength fiber fabric serves as a pad and a second line of defense for body armor, absorbing and diffusing the energy of the remaining part of the bullet and acting as a buffer, thereby reducing non-penetrating damage as much as possible. In these two bulletproof processes, the previous one played a major role in energy absorption, greatly reducing the penetration of the projectile, which is the key to bulletproof.

How to maintain bulletproof vest?

1. Regular cleaning

If you want to extend the service life of body armor, it is very important to keep body armor clean and clean. Body armor jackets can be washed in the washing machine, but you must make sure that the body armor chip is removed before putting it into the washing machine.

When cleaning the bulletproof chip, you need to prepare a sponge and a small bottle of detergent. Use the sponge to dip the detergent to gently wipe the surface of the chip. Remember not to immerse the chip in water or iron the chip cloth with an ironing board. The folds are very easy to scald the cover cloth if you are not careful, which will cause the chips to be eroded by the air or the moisture and stains during use, which will cause the bulletproof function to decline in the long run.

2. Avoid exposure to sunlight

Exposure to sunlight will accelerate the aging of material fibers, thereby reducing its service life and anti-ballistic performance.

3. usage frequency

The bulletproof performance of the body armor is also related to the length of use. The longer the time of use, the lower the ballistic performance and the shorter the validity period. Therefore, if conditions permit, it is best to prepare a replaceable body armor. Can extend the service life of body armor as much as possible.

4. Replace damaged body armor in time

The bulletproof vest should be replaced as soon as it is hit by a bullet, because even if the bulletproof chip hit by the bullet is not damaged in appearance, a strong impact will inevitably lead to a change in the microstructure of the material, thereby affecting its structural stability and ballistic resistance, if not timely Replacement, once the bullet hits the same position during the next use, the possibility of the chip being broken will be greatly increased, so from the perspective of its own safety, the bulletproof vest that was hit by the bullet must be replaced in time.

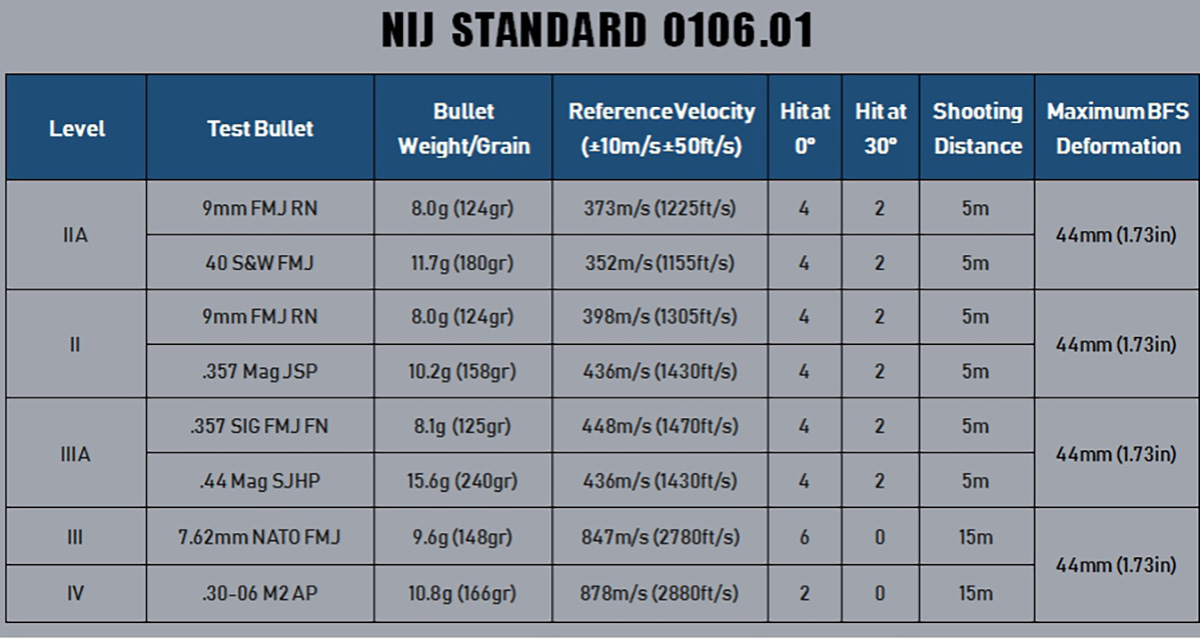

Understanding of NIJ Standard

You'll see things like IIIA and IV across our site.These signify the stopping power of the armor.Below is a very simplified list and explanation.

IIIA = Stops select pistol bullets - Example: 9mm & .45

III = Stops select rifle bullets - Example: 5.56 & 7.62

IV = Stops select AP (Armor-Piercing) bullets - Example: .308 & 7.62 API

Quick Maintenance Guide of Bulletproof Vests:

Safe Use:

Any body armor you buy from anywhere.

Use for 5 years with proper care.

Cleaning Bulletproof Vests:

Separate body armor from carrier. Begin by carefully scraping off large mud clumps.

Use warm water and a soft brush to gently clean remaining stains (Only apply water to brush).

Let air dry away from the sun. *Most of our vests are machine washable and you can skip this if there is a "Machine Washable" tag.*

Cleaning Carrier Vests:

Separate all parts. Begin with carefully scraping off large mud clumps.

Use warm water and a soft brush to gently clean remaining stains.

Let air dry away from the sun.

Care of Body Armor:

Do not wash. Do not leave in sunlight. Do not soak in water.

Body armor isn't washable. If damaged, replace as soon as you can.

What is V50?

The 50 test is used to measure the resistance of a material against fragments. The standard was originally made for bullet proof helmets, but today it is used for all situations where fragments can occur. It is also used for bullet proof vests, riot equipment and ballistic plates.

To measure the V50 value, different FSPs (fragments) are used where the most normal size is 1.1g. This fragment is fired at with different velocities, to measure the resistance of the material against fragments.

The most common standards for testing the fragmentation resistance of a ballistic product are:

US Standard - Mill STD 662 E

UK Standard - UK / SC / 5449

NATO Standard - STANAG 2920

Why is a bullet proof vest not stab proof?

This is a question that we have been asked many times. A bullet proof vest is as default designed to stop bullets, and not stab or spike instruments. For a bullet proof vest to be stab proof as well, it needs to be able to stop the lowest stab resistant level, which for both HOSDB and NIJ is 24 (E1)/36(E2) joules from a engineered blade.

A normal bullet proof vest that is designed only to stop bullets will be able to stop 5-10 joules depending on what material it is made of. This is 1/3 of the required pressure a stab proof vest needs to stop.

A stab proof vest will first be stab proof when it can stop the minimum requirements for a stab proof vest according to NIJ 0115.00 and HOSDB where the lowest level of protection is level 1.

Everything below level 1 (below 36 joules) will be easy to penetrate as it is possible to penetrate a level 1 stab proof vest with a hard stab.

What is BFS/BFD? (Back face signature/Back face deformation)

Back face Signature/Deformation is the depth into the “body” when a bullet strikes the bullet proof vest. For bullet proof vests according to NIJ standard 0101.06, the depth of a bullet impact needs to be less than 44 mm. According to HOSDB and the German Schutzklasse Standard Edition 2008, the depth cannot exceed 25 mm for HOSDB.

Back face signature and Back face deformation are terms used to describe the depth of the bullet impact.

Bullet proof vests made according to NIJ standard are made to stop a .44 Magnum, which is one of the world's most powerful small arms. This also means that body armor designed for the American NIJ standard may be heavier than vests designed for the German SK1 standard.

What is Blunt Force Trauma

Blunt force trauma or blunt trauma is the damage your internal organs will have on a bullet impact. The maximum depth of which must be less than 44 mm. according to the NIJ standard 0101.06. At the same time, the term is also used in relation to Body armor that provides a good blunt force trauma against batons, baseball bats and similar blunt force objects where the stab proof vest more or less stops the blunt force trauma from the hitting object.

Post time: Jul-01-2020